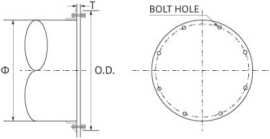

SUS304/ Teflon Coating End Cap

|

Article No. |

I.D. (mm) |

O.D (mm) |

Reinforcement Type |

B.C. |

Thickness (mm) |

|

EC-0100 |

103 |

153 |

|

133 |

3.0 |

|

EC-0150 |

153 |

203 |

|

183 |

3.0 |

|

EC-0200 |

203 |

257 |

|

233 |

3.0 |

|

EC-0250 |

253 |

307 |

|

283 |

3.0 |

|

EC-0300 |

303 |

367 |

|

340 |

3.0 |

|

EC-0350 |

353 |

417 |

|

388 |

3.0 |

|

EC-0400 |

403 |

467 |

|

438 |

3.0 |

|

EC-0450 |

453 |

517 |

|

490 |

3.0 |

|

EC-0500 |

503 |

583 |

|

544 |

3.0 |

|

EC-0550 |

553 |

633 |

|

594 |

3.0 |

|

EC-0600 |

603 |

683 |

|

644 |

3.0 |

|

EC-0650 |

653 |

733 |

|

694 |

3.0 |

|

EC-0700 |

703 |

783 |

|

744 |

3.0 |

|

EC-0750 |

753 |

833 |

NO |

794 |

3.0 |

|

EC-0800 |

803 |

883 |

or |

844 |

3.0 |

|

EC-0850 |

853 |

933 |

cross |

894 |

3.0 |

|

EC-0900 |

903 |

983 |

Cross Tie Bar |

944 |

3.0 |

|

EC-0950 |

953 |

1033 |

Double cross+flange |

994 |

3.0 |

|

EC-1000 |

1003 |

1083 |

|

1044 |

3.0 |

|

EC-1100 |

1103 |

1183 |

|

1144 |

3.0 |

|

EC-1200 |

1203 |

1283 |

AXT on |

1244 |

3.0 |

|

|

|

|

2 X C ross Tie Bar |

|

|

|

EC-1300 |

1303 |

1383 |

|

1344 |

3.0 |

|

EC-1400 |

1403 |

1483 |

or |

1444 |

3.0 |

|

EC-1500 |

1503 |

1583 |

Double cross+flange |

1544 |

3.0 |

|

EC-1600 |

1604 |

1704 |

Trellis |

1644 |

3.0 |

|

EC-1700 |

1704 |

1804 |

2X2 Cross Tie Bar |

1744 |

3.0 |

|

EC-1800 |

1804 |

1904 |

|

1844 |

3.0 |

|

EC-1900 |

1904 |

2004 |

|

1944 |

3.0 |

|

EC-2000 |

2005 |

2105 |

|

2044 |

3.0 |

Note:

Duct diameter over 2000mm is available on request.

Duct thickness is built on SMACNA "round industrial duct construction standards** classes 1 and 5 at pressure -2500Pa (-10 in.wg) .And it also can be changed as customer's request.

1. The part of the air duct to be painted (including the flange surface inside the pipe) must be sandblasted, the sandblasting roughness must meet the roughness of 3.0 G/S76, 40μm or more, and the residual sand particles and metal dust outside the pipe must be removed after sandblasting. Confirm whether the surface of the duct workpiece is clean and the workpiece is covered with aluminum foil.

2. Pull the pipe fittings into the coating room, start painting, spray with electrostatic powder coating machine and extended spray gun tube, adjust the sintering time moderately according to the characteristics of raw materials for 15~20 minutes, and the sintering temperature range is 285°~300°C.

3. After the workpiece is completed, the outside of the tube is affixed with FM certification label, QC serial number and product specification label. The flange mouth is sealed with PE plate or PP hollow corrugated board, and fixed with plastic hose tape.

4.Duct diameter over 2000mm is available on request. Duct thickness is built on SMACNA. And it also can be changed as customer’s request.